Como todos nós sabemos que revestimento de telhado é crucial. Protege as áreas mais vulneráveis de um telhado, como costuras, juntas e bordas, direcionando a água da chuva para longe deles. Isso evita danos causados pela água nas partes do telhado mais propensas a vazamentos, protegendo assim a integridade estrutural de todo o sistema do telhado.

O que é revestimento de telhado?

R O flashing OOF é uma chapa fina e moldada de metal, como aço galvanizado, alumínio ou cobre, usada para criar uma vedação à prova d'água e direcionar a água para longe de pontos críticos do telhado, como chaminés, aberturas de ventilação, claraboias e interseções entre paredes e telhado. Ele evita que a água penetre na estrutura do telhado, o que pode causar vazamentos, deterioração da madeira e danos estruturais. A instalação adequada e o tipo certo de flashing para o perfil do telhado são essenciais para um telhado metálico impermeável e duradouro.

Qual é o material do revestimento do telhado?

|

|

Aço galvanizado , um material comum, econômico e durável.

|

O aço galvanizado é um material de revestimento popular e resistente à corrosão que os empreiteiros dobram facilmente para um ajuste personalizado. |

|

|

Alumínio , eu leve, resistente à corrosão e fácil de dobrar.

|

O revestimento de alumínio é leve e maleável, mas requer revestimento protetor contra materiais alcalinos, como alvenaria ou água salgada. |

|

|

Cobre , um outra opção premium conhecida por sua resistência à corrosão.

|

Considerações sobre a instalação . O revestimento de cobre combina com telhados ou luminárias existentes, geralmente usado para revestimento de degraus e desenvolve uma pátina verde com o tempo. |

Qual é a principal função do revestimento do telhado?

☆ Redirecionamento de Água

Sua função principal é direcionar a água da chuva e a neve derretida para longe das emendas, juntas e projeções do telhado, evitando que a água penetre no sistema do telhado.

☆ Impermeabilização

Ele atua como uma barreira à prova d'água, selando vãos entre diferentes materiais de telhado ou entre o telhado e superfícies verticais.

☆ Proteção Estrutural

Ao evitar a infiltração de água, o revestimento ajuda a proteger o telhado subjacente, o isolamento e o interior do edifício contra danos causados pela umidade, mofo e apodrecimento.

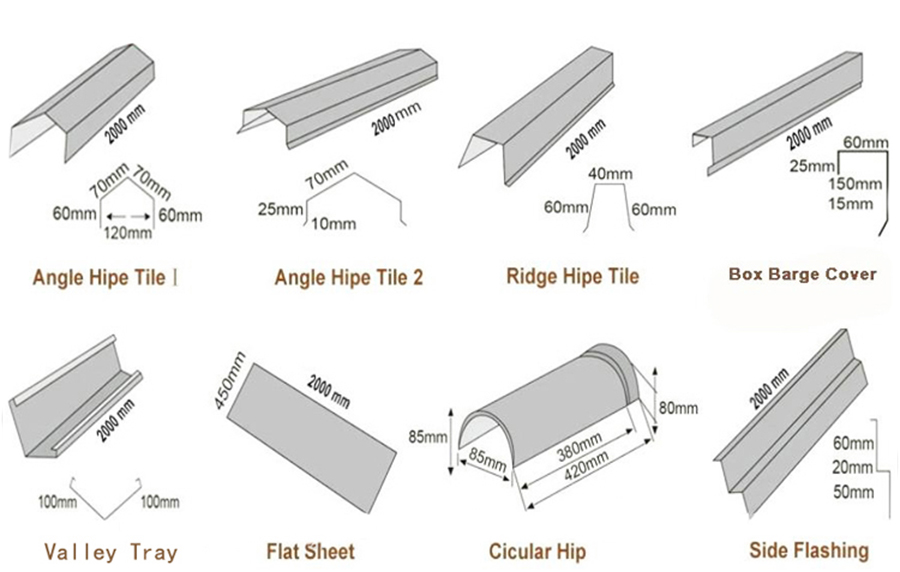

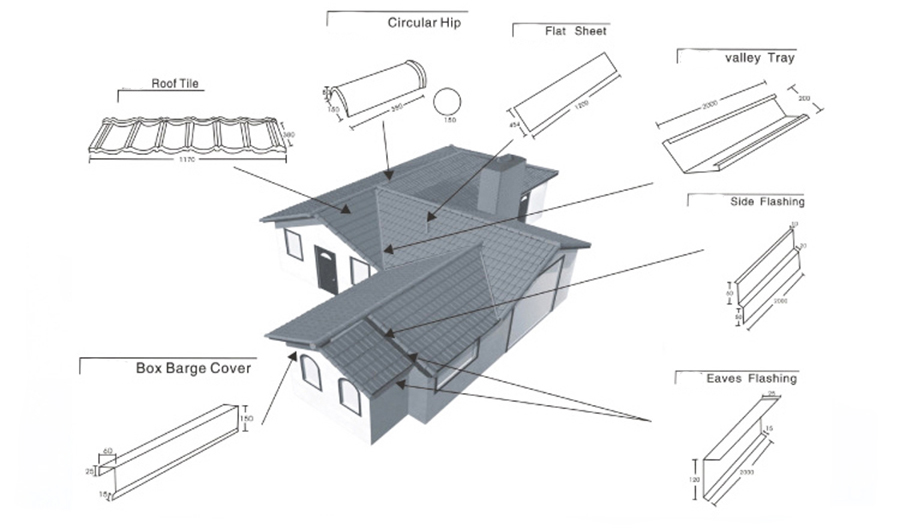

Tipos comuns de revestimento de telhado

☆ Piscando em degraus

Instalado onde um telhado encontra uma parede inclinada, como ao redor de uma mansarda, com cada peça sobrepondo a de baixo para criar uma barreira em forma de degrau contra a água.

☆ Pisca-pisca de gotejamento/placa de barcaça

Usado ao longo das bordas do telhado (beirais e frontões) para direcionar a água para longe da fáscia e das paredes.

☆ Vale piscando

Cobre o "vale" onde dois planos de telhado se encontram, proporcionando um canal estanque para a água escoar.

☆ Pisca-pisca de chaminé e ventilação

Feito sob medida para se ajustar ao redor de chaminés, tubos de ventilação e outras penetrações, impedindo a entrada de água por essas aberturas.

☆ Cobertura de cumeeira

Cobre o topo de um telhado inclinado, proporcionando uma vedação estanque onde duas inclinações do telhado se encontram no topo.

Considerações sobre a instalação

☆ Compatibilidade

O revestimento deve ser compatível com o perfil e o formato específicos dos painéis metálicos do seu telhado.

☆ Vedação adequada

Todas as sobreposições do revestimento devem ser devidamente seladas e os fixadores devem passar pelo selante.

☆ Manutenção

Inspeções e manutenções regulares são cruciais para garantir que o revestimento permaneça em boas condições e forneça uma vedação eficaz.

Em resumo, o revestimento de telhado é um componente essencial para qualquer sistema de cobertura durável. Ao direcionar estrategicamente a água para longe de áreas críticas como vales, chaminés e aberturas, ele fornece proteção vital contra vazamentos e danos causados pela água. Investir em materiais de revestimento de alta qualidade — como alumínio, cobre ou aço galvanizado — e garantir uma instalação profissional são essenciais para um desempenho a longo prazo. A manutenção adequada do revestimento do telhado protege sua casa ' A estrutura, aumenta a eficiência energética e prolonga a vida útil de todo o seu telhado. Nunca subestime esta camada crucial de defesa para sua propriedade.

Caso tenha alguma dúvida sobre instalação de flashing de telhado, envie os desenhos quando disponíveis. Para qualquer dúvida, entre em contato com a equipe da Yumisteel. Obrigado. !

anos de experiência

serviço on-line

serviço on-line +86-592-6095031

+86-592-6095031 manager@yumisteel.com

manager@yumisteel.com Alina_Yuki

Alina_Yuki +8613559086380

+8613559086380 +8615860744964

+8615860744964